|

¡¡

Plastic deformation theory

Plastic deformation theory

¡¡

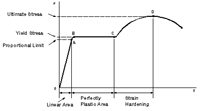

If a deformation of steel due to

load returns in original state as a load deletes, it is said to

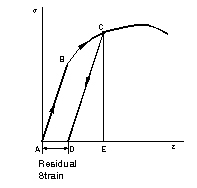

linear and elastic behavior. However, when the load is reduced, the

strain decreases along an almost unloading line CD which is parallel

to the initially linear region of curve. When the load is again zero

at the end of unloading, the strain is not zero ; there remains a

residual strain AD. The irrecoverable strain AD is referred to as

plastic strain while the recoverable strain CE is the elastic

strain. The graph follows.

The advantage of this method fellows.

Other methods consider only elastic

area and pre-camber according to design dead load. but these

methods very inconvenient and difficult. while our method considers

plastic and elastic area so initially H-beam is cambered by pre-loading

over elastic area. existing method makes use of a fixed support

so very inconvenient, while our method chooses simple support, so

this is very useful. this method can be applied simple and continuous

preflex beam.

The stress of generally structural

steel |

|

Process of manufacturing preflex composite beam using plastic

deformation of rolled profile

Process of manufacturing preflex composite beam using plastic

deformation of rolled profile

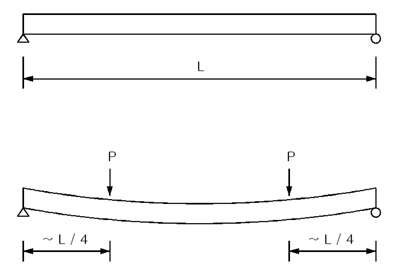

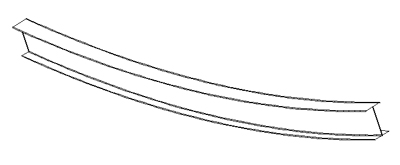

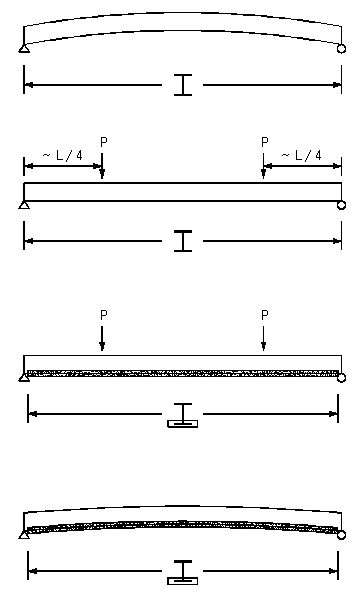

Most of all, a beam is connected

by prestressed steel bar in both ends of beam and by plastic loading

in both quarters of beam, plastic deformation appears. after beams

are turned over, in same course, support is connected by PS bar.

moreover by loading in both quarters of beam, the beams are

made straight then low casing concrete is placed and cured. finally

by unloading low flange casing concrete is introduced prestress.

this is method of manufacturing preflex composite beam.

|

Plastic deformation process |

The plastic deformation of

manufacturing H-shape preflex composite beam |

|

|

Process of manufacturing preflex

beam |

process of manufacturing H-shape

plastically deformated preflex composite beam |

|

|