| |

|

Application of construction

in preflex composite girder with loading |

A SPECIAL FEATURE A SPECIAL FEATURE

1. A summary of the method

(Patent

a public notice Number. 10-2000-0036947),

(Registration number.

20-0196863-0000, Registration number20-0210596-0000)

The building construction

using the basic preflex beam is difficult to obtain

vacant room effectively because

of the bigger negative moment rising in connection

with column of section part than positive moment rising

in central parts when design

load is acted, and brought rusting of steel and a declination

of durability because of rising

cracks of concrete , and gave damages of connection

parts of a pole and a crossbeam, and gave magnification

of column section because of

increasing of dynamic load being due to excessive dead

load.

the applicable method

of the successive preflex composite beam using loading

produces positive moment with stocking a little load

to the central parts of Beam

after leaving preflex beam producing as simple beam

state simply between pole and

pole, and decline tensile force confronting design load

with using a compressed power of beam section part originated

from excluding the stocked load

after continuity with connecting preflex beam and beam

by welding

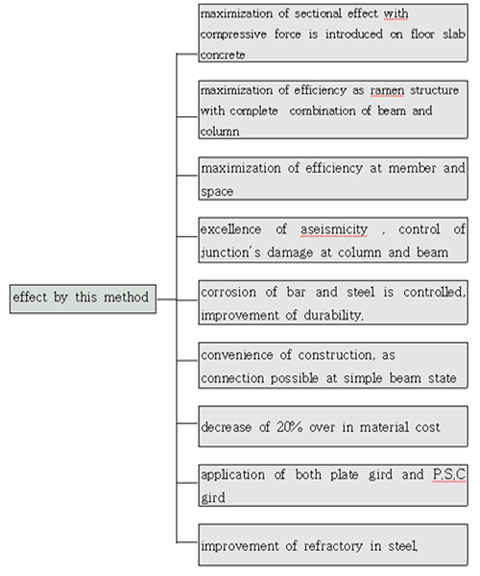

2. effect

·

the continuous structure using the basic preflex composite

girder was unavoidable interpretation,

but preflex composite girder using this method

can maximize a section effects being

due to possibility of interpretation as composite

beam

· efficiency as rahmen

can be maximize because perfect firmness is possible

between beam and pole

· that can maximize the efficiency

of member and space

· that can repress damages of

connection between pole and beam effectively and

aseismicity is excellent.

· rusting of bar and steel can

be improved being due to controling fissures rising

from floor slab concrete

· Construction is easy and reliable

because this method connect between beam and

beam inside pole of simple beam situation.

· when you apply this method ,

you can decline about 20% of the material cost.

· this method can be applied

to plate girder, p.s.c girder, and so on as well.

|

¡¡

Application of construction

in preflex composite girder with loading |

THE METHOD OF MAKING

THE METHOD OF MAKING

1. we make a large quantity of preflex beam

in factory and transport to the actual spot

of cause, we can make in the actual spot.

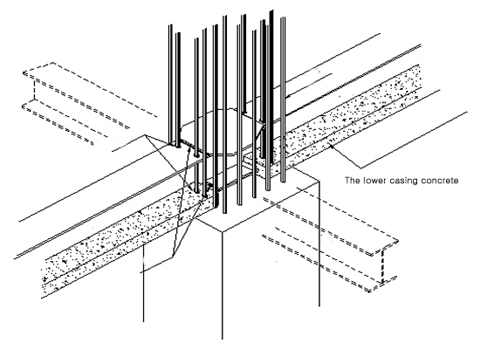

2. in case of concrete pole , we should do

placing and curing pole ,

and should draw out steel which is needed in case of

steel composite pole, we should

do placing and curing concrete in low parts

which is stayed by beam , and

we should obstruct bucking of pole, and we should make

a situation of putting

simply preflex composite beam, welding braket to the

web part of steel.

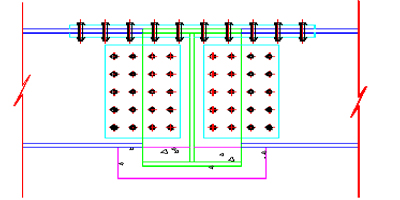

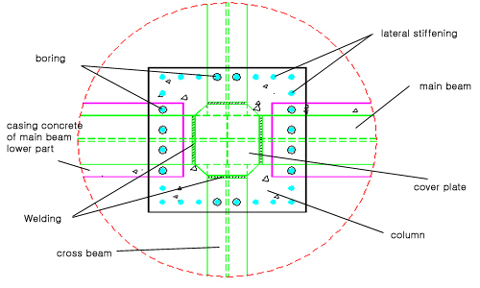

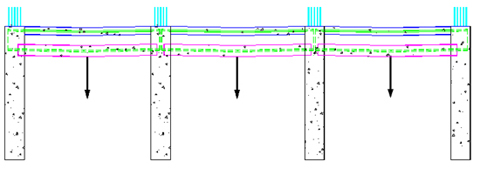

Fig 1 Concrete Column

Fig 2 Steel Composite Column

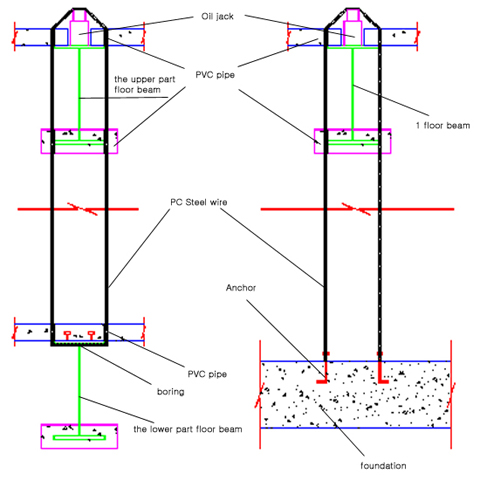

3. you should leave simply preflex to the pole

in this time , in concrete cases , you

should do boring to the lower part casing concrete of

section part and to the upper-lower

part flange, and then you should help steel of pole

can be penetrated.

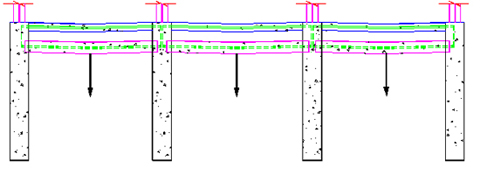

Fig 3 Concrete Column

¡¡ |

¡¡

Application of construction

in preflex composite girder with loading |

Fig 4 Steel Composite Column

4. you connect lateral stiffening , at this

time , in case of concrete pole , you do boring

to the upper-lower part flange laying in the pole ,

and then you do penetrate steel.

you connect span central lateral stiffening with preflex

beam as main beam in similar

methods like picture 5.

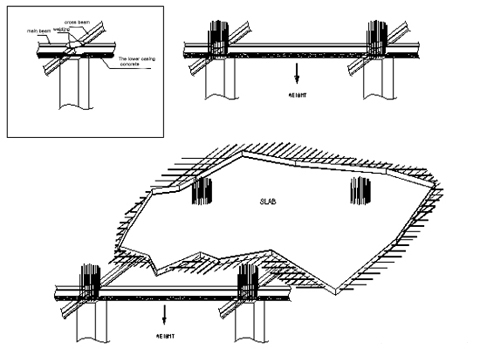

picture 5. - connection details picture

of preflex beam and lateral stiffening

main

beam cross beam The lower casing concrete

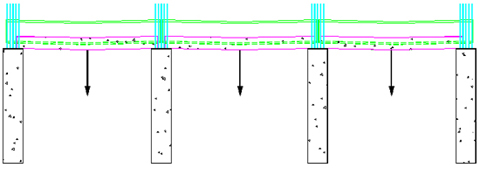

5. you do stock vertical load to the preflex

beam leaving , you can do stock load

with establishing anchor in basic bottom in first floor,

you can do stock load with laying

in floor slab concrete and coiling in the main beam

of lower part floor pc strong

line in second floor , the picture 8 shows the picture

of bending moment being owing

to self load and load stock, and picture 9 express the

methods stocking load with being

tense pc strong line as tension equipment ,and

express the methods stocking load with laying in anchor

in the basic bottom as basic

picture.

picture 6- situation picture of stocking

load to the preflex beam in cases of

¡¡ |

¡¡

Application of construction

in preflex composite girder with loading |

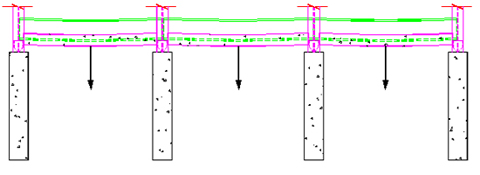

picture 7. situation picture stocking

load to the preflex in cases of steel composite column.

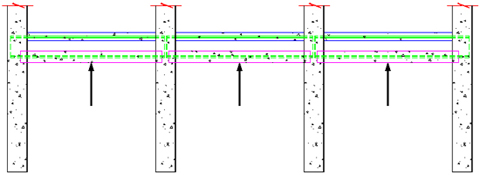

picture 8. Moment picture of preflex

as beam self load and load stock

¡¡ |

¡¡

Application of construction

in preflex composite girder with loading |

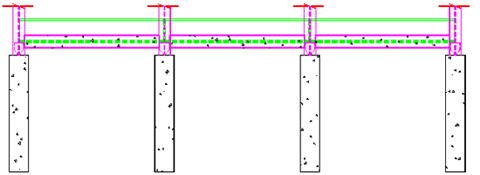

6. in cases of concrete pole ,

we do weld and connect using cover plate between

preflex beam as main beam of simple setting state

and beam in cases of steel composite

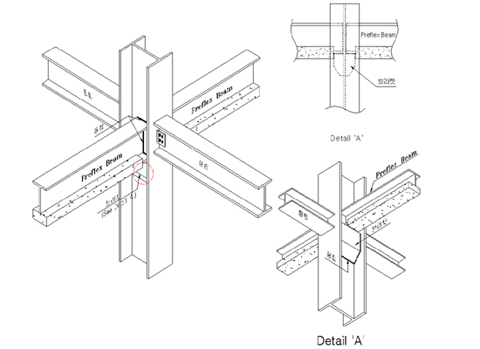

pole, we make successive structure with welding and connecting preflex beam using joint bar in the web part of pole. the picture 10~12 show details of

connection between main beam and lateral stiffening

to the part of pole in case of concrete pole. he

picture 13 shows details connection

between main beam and lateral stiffening in

case of steel composite column

Fig 10

Fig 11

¡¡ |

¡¡

Application of construction

in preflex composite girder with loading |

Fig 12

¡¡

Fig 13

¡¡ |

¡¡

Application of construction

in preflex composite girder with loading |

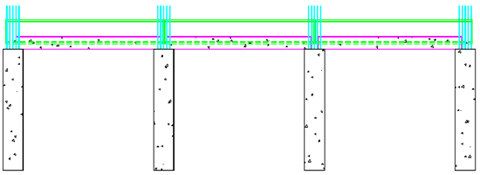

7. Upper column, floor

slab have simultaneous placing and curing. As

column and beam become one body , they can composed

behavior in given load. Picture

16 is bending moment diagram that is happened in preflex composite beam of continuous

structure state about load of it hasn't set concrete.

Picture 14 concrete column

¡¡

Picture 15 Steel composite column

¡¡

Picture 16 that is happened

in preflex composite beam of continuous structure state

about load of it hasn't set concrete.

¡¡

8. Surcharged load is remove. This time, as

bending moment of picture 18 is happened.

as a result of this, section of beam is introduced

and negative moment by service

load is resisted as floor slab and composited beam.

¡¡

Picture 17 upward force by removed

weight

¡¡ |

¡¡

Application of construction

in preflex composite girder with loading |

Picture 18 bending moment diagram

of preflex composite beam is happened by load

removed.

From picture 1 to picture 18, the negative

moment section of the construction process introduced

compressed stress and have resisted negative moment

by dead load, service load.

Because

this method have decreased exaggerative moment at union

part of beam and column, can prevent a lack of

water by union part floor concrete's crack at

previous construction.

So this has not only

improvement of endurance but also decrease of

column section as well as decrease of beam steel

height. As this result can cut down on material

cost, maximize efficiency of space, make possible production

of construction that have improved aseismicity

by self load reduction of beam and continuance.

This method can applied not only preflex beam

but also P.S.C continuance beam, Plate gird, steel

box. naturally this method can applied on repetition

of a same way at continuance of 3 span over.

¡ß If show by a diagram construction

step and way of this method.

|

¡¡

Application of construction

in preflex composite girder with loading |

example of a

design example of a

design

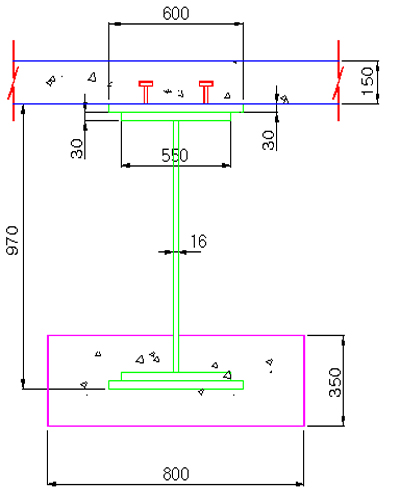

1.examination

section in case of possession load 0.5 ton/m2 (Using

of SWS 490) - when

load 20 ton.

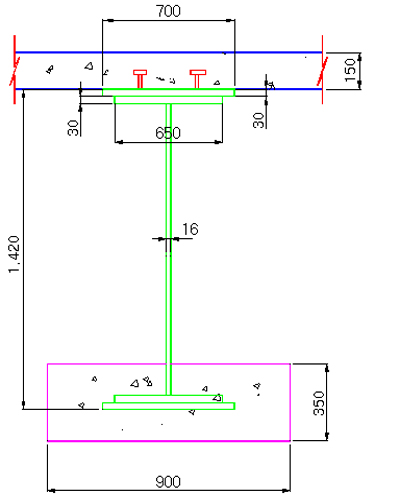

picture19

¡ß Section of inner

part span length 30m part by this loading used method

1. To simplicity of

structural calculation, selection predicted the upper

center part

that will get the most load. Span of main beam

is 25.0m+30.0m+25.0m=80.0m, Modelling Space of main beam is 3@10.0m =30.0m.

2. Structural system is modeled

classified by each construction stage that presented

above.

3.Computation of

load

-

acting possession load on floor slab : 0.5 ton/m2

-

Self load of lateral stiffening member. :0.12 ton/m

- Self load

of slab : is applied load of 0.375 ton/m2 over

4. Stress examination

Examination

of stress is examined that the most moment is applied

30m span's

main beam as steel upper flange's stress of negative

moment part in preflex

composite beam and lower casing concrete's stress of

span center part.

-The section property

¡¡ |

negative

moment part |

positive moment part

steel + lower casing concrete

¡¡ |

steel

+lower casing concrete +floor slab |

I |

1516520.8

¡¡ |

2052417.5 |

2723094.6 |

Yu |

48.5

¡¡ |

62.2 |

69.2 |

YL |

48.5

¡¡ |

47.8 |

55.8 |

¡¡ |

¡¡

Application of construction

in preflex composite girder with loading |

|

stage |

moment(t.m)

|

stress(Kg/§²) |

part of end |

center |

steel

upper flange of end part |

lower

casing concrete of center

¡¡ |

preflex beam

(early creep, early

shrinkage, consideration of self load)

¡¡ |

|

|

0 |

-165.85 |

loading

¡¡ |

0 |

150 |

0 |

46.6 |

Self loading of floor

concrete and lateral stiffening member.

¡¡ |

-340.6 |

180.6 |

1089.5 |

56.1 |

Removal

of load

¡¡ |

77.8 |

-81.4 |

-155.0 |

-22.2 |

loading

of occupation load

¡¡ |

-371.5 |

217.3 |

739.5 |

59.4 |

Sum

¡¡ |

¡¡ |

¡¡ |

1465.5 |

-26.0 |

-The next is expressed

stress of section that in case of unloading and considering

by classified loaded magnitude in 30m section.

a

reference |

steel

upper flange's stress of negative moment

part |

lower casing concrete's stress of

span cente

¡¡ |

unloading

¡¡ |

2097 |

-50.4 |

loading

5ton of this method

¡¡ |

1603 |

-44.3 |

loading

10ton of this method

¡¡ |

1557 |

-38.0 |

loading

15ton of this method

¡¡ |

1511 |

-32.0 |

loading

20ton of this method

¡¡ |

1465 |

-26.0 |

¡Ø here, in case of unloading, the reason

that stress of steel upper flange in negative

moment part grow bigger suddenly, compressed stress

hasn't introduced

on floor slab concrete of section part by loading removal

so because it isn't

considered as composite section.

|

¡¡

Application of construction

in preflex composite girder with loading |

2.

examination section in case of possession load 1.2 ton/m2

(Using of SWS 490)

picture20 Section of inner part span length

30m part by this loading used method

- At same condition such (1), Only possession

load applied as 1.2 ton/m2.

- The

next is expressed stress of section that in case of

unloading and considering

by classified loaded magnitude in 30m section.

a

reference |

steel

upper flange's stress of negative moment

part |

lower casing concrete's stress of

span cente

¡¡ |

unloading

¡¡ |

2051 |

-66.7 |

loading

5ton of this method

¡¡ |

1528 |

-63.8 |

loading

10ton of this method

¡¡ |

1500 |

-60.8 |

loading

15ton of this method

¡¡ |

1473 |

-57.8 |

loading

20ton of this method

¡¡ |

1446 |

-54.8 |

¡Ø

here is on equal terms, in case of unloading, the reason

that stress of steel upper

flange in negative moment part grow bigger suddenly,

compressed stress

hasn't introduced on floor slab concrete of section

part by loading removal

so because it isn't considered as composite section.

|

¡¡

Application of construction

in preflex composite girder with loading |

effect by this method effect by this method

As mentioned,

compared with section of previous preflex continuance

beam that can maintain stress of negative

moment part in similar level, section of

this method can reduce about 5% of steel and 45% of

the lower casing concrete.

¡¡ |

|

|

|

|