|

The new method of preflex beam

The new method of preflex beam

¡¡

The abstract of Preflex Beam The abstract of Preflex Beam

¡¡

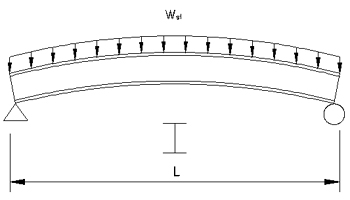

The Preflex composite girder is

well-known and constructed worldwide. It was initially proposed

by the Belgium designer of structure , A. Lipski in 1949. From 1951

to 1954 A. Lipski and professor L. Bases, Brussel Univ. jointly

researched and developed the Preflex composite girder bridge. It

makes up for the weak point of concrete which is brittle and weak

in tensile. Now the superiority of Preflex composite girder bridge

is guaranteed worldwide. The pre-compressed casing concrete covering

tensile flange can counterbalance tensile stresses due to dead and

live load. This method is an economical method of construction and

its characteristic is as follow.

The safety and durability The safety and durability

¡¡

The Preflex composite girder is

safer than other steel girder or concrete girder under service load

because maximum bending tensile and compressive stresses occur when

it is manufactured.

It has bigger rigidity, corrosion

resistance and durability because its lower flange is covered with

high strength concrete and the whole steel girder is covered with

concrete.

¡¡

The workability and availability The workability and availability

This method can reduce a term of

work for using Preflex girder manufactured in factory and can reduce

construction price because we can construct slab without additional

support system.

If you apply the method under following

conditions, you can take advantage of its merits because of relatively

lower height of girder.

¨ç In case of limited height of

girder for changing work to repair river.

¨è For reducing maintenance expenses

or getting easiness of construction.

¨é When we construct grade separation,

subway and pedestrian over bridge that must make space under bridge,

Preflex composite girder is applied in form of simple beam or continuous

beam and nowadays Preflex composite girder of block form constructed

is using.

¡¡

The comparison with a bridge

that is using other method of construction. The comparison with a bridge

that is using other method of construction.

It is the one of the best advantages

that we can reduce height of girder. It is widely known that it

can has 45 of span-height ratio and 50 of the least height of girder.

We can say that Preflex coposite

girder is safer from fatigue than common plate girder because the

range of stress the former is smaller than that of latter.

Because it has bigger rigidity than

common plate girder, deflection and vibration is very small. And

the maintenance expense is cheaper because it is covered with concrete

completely.

¡¡

2nd prestressing for simple and continuous preflex composite beams

2nd prestressing for simple and continuous preflex composite beams

¡¡

2nd prestressing for simple preflex composite beams using PC steel

bar

2nd prestressing for simple preflex composite beams using PC steel

bar

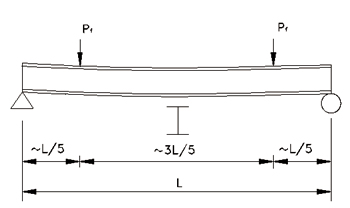

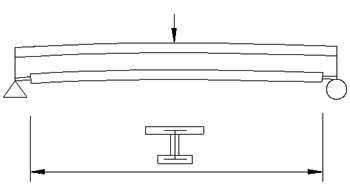

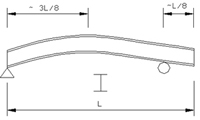

An outline of the above method is

as follow.

In advance set Preflex composite

girder beam manufactured in factory or field between abutment or

bridge pier. And after connecting end of beam with PC steel bar

by using anchor plate, equip hydraulic jack 1/3§¤point from end

of bridge on either side. By use of this hydraulic jack tense the

PC steel bar then cast and cure concrete when bending occurred at

beam. Next remove the PC steel bar so give additional compressive

stresses to lower part of beam at range of the positive moments.

Contents of construction |

Procedure of construction |

Setting Preflex composite

girder beam |

|

Connecting steel bar, Installing

hydraulic jack and Loading by steel bar |

|

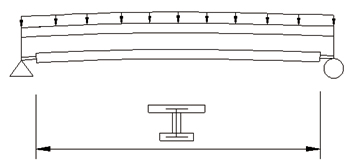

Casting Slab In Condition

of Loading |

|

The secondary tensing steel

bar right after casting slab - Supplement of compressive

stresses loss which is occurred right before curing |

|

Paving asphalt after removing

steel bar and hydraulic jack - Diagram of normal stress

and moments |

|

Classification |

Detail drawing and foreground

of experiments |

Detail dra-wing of conn-ecting

steel bar with anc-hor plate |

End |

|

Mid span |

|

Connecting

steel bar with anchor plate |

|

|

. |

|

¡¡

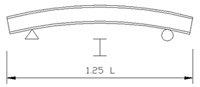

2nd prestressing for simple preflex composite beams by lifting

temporary support

2nd prestressing for simple preflex composite beams by lifting

temporary support

Contents of construction |

Procedure of construction |

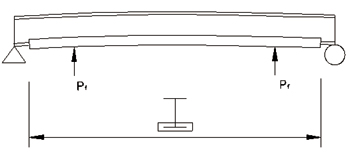

Setting Preflex steel girder |

|

Preflexion loading at

about L/5 point from both of ends |

|

Casting concrete at lower

flange and releasing stresses |

|

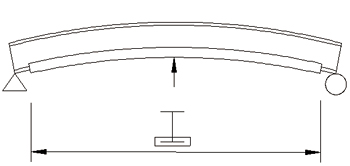

Lifting up sub-support at

mid span |

|

Casting concrete of slab and

web |

|

Lifting down sub-support |

|

Paving asphalt |

|

|

Execution of work |

Foreground of installing sub-support |

|

¡¡

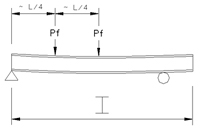

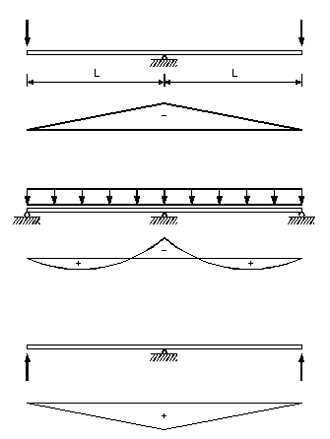

2nd prestressing for simple preflex composite beams by shifting

down-up support

2nd prestressing for simple preflex composite beams by shifting

down-up support

¡¡

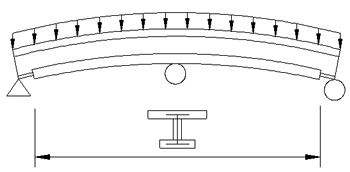

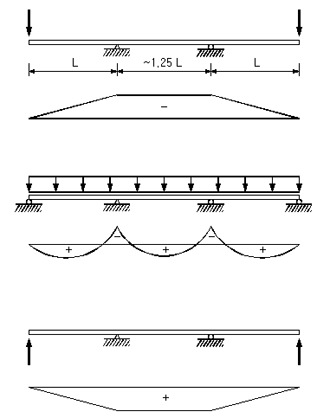

First convert hinge support to fixed

ends on simple beam structure system and lift down roller support

to give additional compressive stresses to lower flange. In this

condition cast slab concrete. After the slab concrete is cured,

lift up the roller support for giving compressive stresses corresponding

to negative moments of fixed ends to slab concrete.

¡¡ |

Procedure of construction |

States and moments according

to stages diagram in case of using Down-up method |

|

|

Detail drawing |

Connecting Preflex beam with

bridge pier at fixed support |

|

¡¡

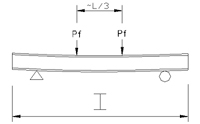

The manufacturing method of inner and outer preflex girder for

manufacturing continuous preflex composite beams

The manufacturing method of inner and outer preflex girder for

manufacturing continuous preflex composite beams

In the first place, manufacture

Preflex girder in lots according to inner and outer span to make

Preflex beam of continuous beam. The next give secondary prestressing

by Down-up method after connecting inner and outer Preflex girder

according to each span. The progress of construction Preflex composite

girder is as follow.

Contents of construction |

Procedure of construction |

Outside beam |

Inside beam |

Setting Preflex steel girder |

|

|

Loading Preflex loads |

|

|

Casting lower flange concrete |

|

|

Release |

|

|

¡¡

2nd prestressing for 2 spans continuous preflex composite beams by

shifting down-up support(type separated beam from pier)

2nd prestressing for 2 spans continuous preflex composite beams by

shifting down-up support(type separated beam from pier)

First connect two external beams

on the inner support. And cast slab concrete in condition that both

ends of external beams are lifted down. After the slab concrete

is cured, lift up the both ends of external beams for giving compressive

stresses to slab concrete corresponding to tensile stresses of inner

supports.

|

Procedure of construction |

Setting into simple beam by

shifting inner support of outer span beam |

|

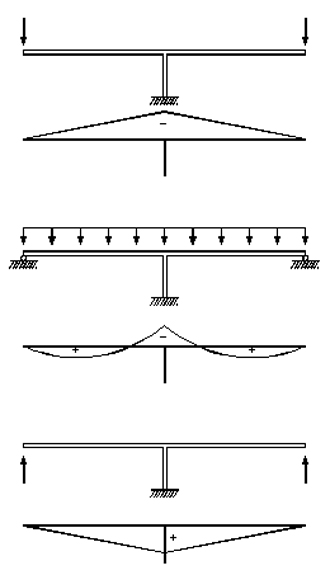

States and moment diagram

according to each stages in case of using Down-up method

after connecting two outer beams with inner support |

|

¡¡

2nd prestressing for 2 spans continuous preflex composite beams by

shifting down-up support(type interated beam from pier)

2nd prestressing for 2 spans continuous preflex composite beams by

shifting down-up support(type interated beam from pier)

The moment that two outer beams

are connected make them be in a body with bridge pier. Then cast

slab concrete in condition that both ends of external beams are

lifted down. After the slab concrete is cured, lift up the both

ends of external beams for giving compressive stresses to slab concrete

corresponding to tensile stresses of inner supports.

¡¡ |

Procedure of construction |

Setting into simple beam by

shifting inner support of outer span beam |

|

States and moment diagram

according to each stages in case of using Down-up method

after connecting two outer beams with inner support) |

|

|

Detail drawing |

Connecting Preflex beam with

bridge pier in one unified body at inner support |

|

¡¡

2nd prestressing for 3 spans continuous preflex composite beams by

shifting down-up support(type separated beam from pier)

2nd prestressing for 3 spans continuous preflex composite beams by

shifting down-up support(type separated beam from pier)

First connect two outer beams with

inner support respectively. Then cast slab concrete in condition

that both ends of external beams are lifted down. After the slab

concrete is cured, lift up the both ends of external beams for giving

compressive stresses to slab concrete corresponding to tensile stresses

of inner supports.

|

Procedure of construction |

States and moment diagram

according to each stages in case of using Down-up method

after connecting two outer beams and inner beams with

inner support respectively |

|

¡¡

2nd prestressing for 3 spans continuous preflex composite beams by

shifting down-up support(type integrated beam from pier)

2nd prestressing for 3 spans continuous preflex composite beams by

shifting down-up support(type integrated beam from pier)

¡¡

The moment that two outer beams

are connected make them be in a body with bridge pier. Then cast

slab concrete in condition that both ends of external beams are

lifted down. After the slab concrete is cured, lift up the both

ends of external beams for giving compressive stresses to slab concrete

corresponding to tensile stresses of inner supports.

|

Procedure of construction |

States and moment diagram

according to each stages in case of using Down-up method

after connecting two outer beams and inner beams with

inner support and making them be in a body simultaneously(Here,

the condition connected beam with bridge pier is same

with the case of 2 spans continuous beam) |

|

|