|

|

|

|

| |

|

|

¡¡

A new

method of manufacturing four preflex beams simultaneously for straight

and curved beam. A new

method of manufacturing four preflex beams simultaneously for straight

and curved beam.

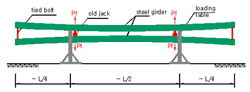

The typical way of producing preflex

composite beam is to make two preflex beams simultaneously by putting

one beam on the top of the loading table and the other beam under

the loading table respectively. However, it is normally said that

this method is faced with the buckling problems as well as long

period of time for producing preflex composite beams at construction

site. Moreover, the existing method could not be applied to any

construction of curved-bridge due to the torsion problem. The new

method developed in this study is to make four preflex beams simultaneously

by putting two beams on the top of loading table and the other two

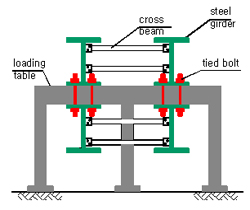

beams under the loading table, respectively. In doing so, we arrange

several diaphragms between two beams to bind tightly so that we

can solve the existing problems such as buckling and torsion. In

addition, the new method enables us to produce curved preflex beams

as well as to save a great deal of construction period with this

new method. furthermore fabr

ic manufacturing is also possible.

¡¡

[Front View] ¡¡ |

[Side View] |

|

¡¡

¡¡

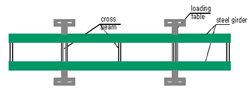

[Ground Plane]

¡¡ |

|

|

¡¡

¡¡ |

|

[Manufacturing steel girder] |

[Setting loading table] |

|

|

¡¡

¡¡ |

|

[Connecting steel girder using tied bolt] |

[Loading] |

|

|

¡¡

¡¡ |

|

[Casting casing concrete] |

[Steam curing] |

|

¡¡

¡¡ |

|

|

[Release] |

[Turn over] |

¡¡

|

|

|

|

|

|

|

|

|

|

|