| |

|

The method of improving stiffness

at the inner support in the steel box girder. |

Because

the construction work of existing steel box composite

girder bridge is faster than the other method,

it has been widely constructed in the inside and outside

of the country. Because

the construction work of existing steel box composite

girder bridge is faster than the other method,

it has been widely constructed in the inside and outside

of the country.

Because of grate the torsion, that

has many advantage for the curve bridge but has

comparative big section, noise and vibration.

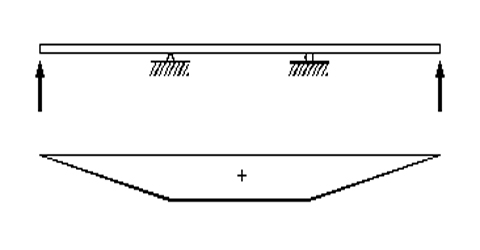

Steel box composite

gird bridge by concrete-fill and lifting support method. Steel box composite

gird bridge by concrete-fill and lifting support method.

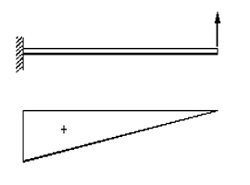

Because

the construction work of existing steel box composite

girder bridge is quick than the other method,

it has widely constructed in the inside and outside

of the country. Because of grate the torsion, that has

many advantage for the curve bridge but has comparative

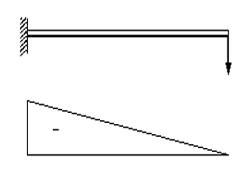

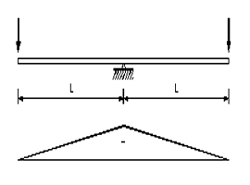

big section, noise and vibration. There are so different

between maximum magnitude of positive moment and

negative moment. The section choice of bridge whole

length is non economic and because the floor

slab's section is large, neutrality axis give way to

the upper part. So the upper and lower stress of

steel not be in balance. The other a fault of previous

steel box girder bridge is extension that happened at

inner support part by additional dead and live load. Therefore

it becomes not composite section, floor slab is

cracked and stiffness is declined. Fault

at welding area is due to the shear flow's disturbance

by changing top and bottom flange thick into various

shape.

Steel box composite gird bridge by concrete-fill and

lifting support method.

Steel box composite gird bridge by concrete-fill and

lifting support method.

(The new method No.270

appointed by MOCT [Ministry of Construction& Transportation])

(Patent a public notice Number. 10-1999-007688)

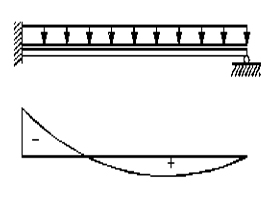

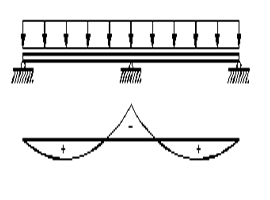

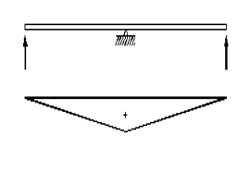

This method's purpose is improving

stiffness necessary to negative moment area by

shear connector installed and casting concrete on the

bottom of the negative moment area of the steel box

to steel box girder.Otherwise, improving stiffness

necessary for taking off tension force when design load

applied by using the up-down method, compressive stress

installed on the negative moment area of upside of deck

plate concrete. This method is more extend a span

of bridge than existed steel box bridge and case

of making a variety section of the positive-negative

moment area, most extend a span of bridge.Otherwise

prevent a decay in the steel box by being installed

concrete at the bottom of the negative moment area and

obtain effect that absorbed noise or shake.And

This method can reduce a fault of welding area by changing

top and bottom flange thick into relatively simple. |

¡¡

The

method of improving stiffness at the inner support in the

steel box girder. |

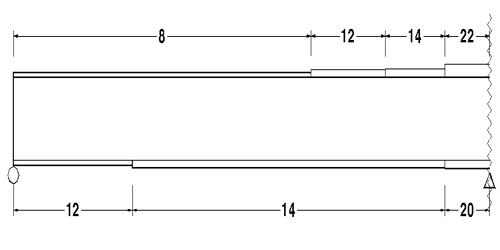

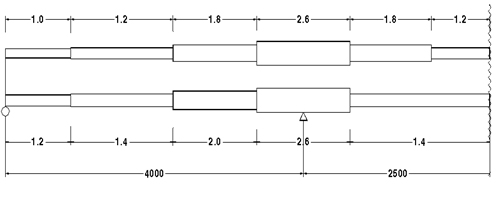

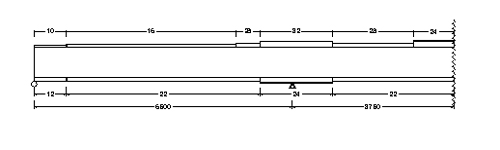

45m 2 span

continuous bridge 's section property and comparison in

the amount of materials 45m 2 span

continuous bridge 's section property and comparison in

the amount of materials

Reduced effect of steel materials.

Reduced effect of steel materials.

flange's thickness and hight's simultaneous

reduction and maximum curtailment of steel

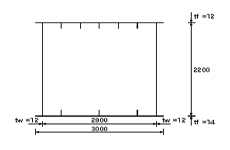

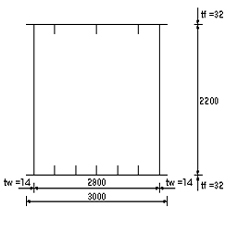

existing steel box gird bridge's section property

existing steel box gird bridge's section property

steel : SM490

concrete : The floor plate -

270 Kg/§²

The main position's section

The main position's section

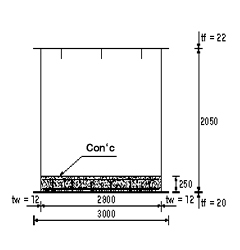

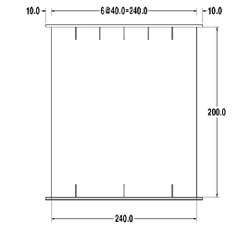

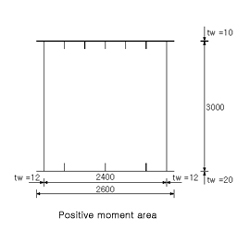

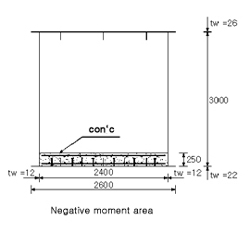

positive moment area |

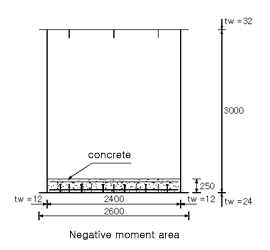

negative moment area |

|

|

TU=1.2cm , TL=1.4 cm |

TU=3.2 cm , TL=3.2 cm |

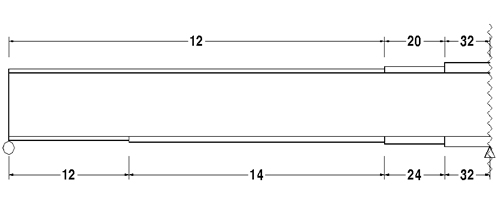

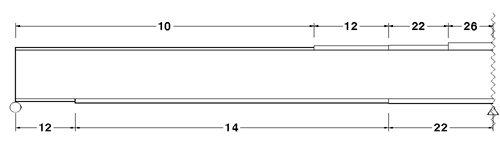

The variation of flange

The variation of flange

|

The

method of improving stiffness at the inner support

in the steel box girder. |

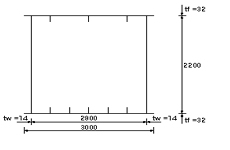

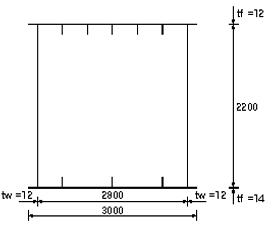

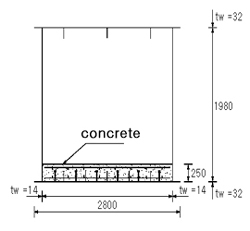

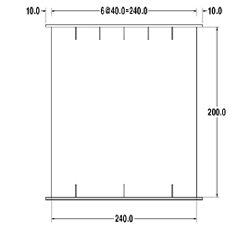

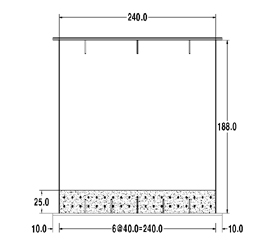

improved steel box

gird bridge's section property improved steel box

gird bridge's section property

steel : SM490

concrete : The floor plate -

270 Kg/§² casting concrete :-400 Kg/§²

The

main position's section The

main position's section

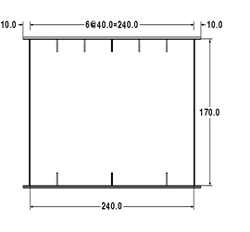

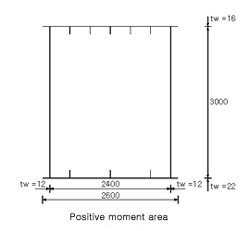

positive moment area |

negative moment area |

|

|

TU=0.8

cm , TL=1.4 cm |

TU=2.2

cm , TL=2.0 cm |

variation of flange variation of flange

The section and the amount of materials's

comparison The section and the amount of materials's

comparison

|

existing |

improved |

existing/improved |

steel |

120.5 |

102.67 |

0.85 |

concrete |

315 |

332 |

1.05 |

section's

girder height |

positive moment area |

2200 |

2050 |

0.93 |

negative moment area |

2200 |

2050 |

0.93 |

girder height 7% reduction

a condition ¡æ15% reduction of steel amount

|

¡¡

The

method of improving stiffness at the inner support

in the steel box girder. |

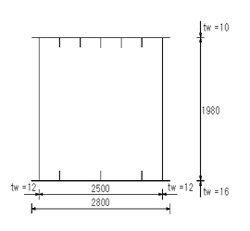

The effect of reduction

on girder height The effect of reduction

on girder height

flange's thickness and hight's

simultaneous reduction and maximum curtailment of

girder height

The

main position's section The

main position's section

positive

moment area |

|

|

negative

moment area |

|

|

The

section and the amount of materials's comparison The

section and the amount of materials's comparison

|

existing method

¡¡

|

Lifting

Support |

L.S/Existing

|

Steel (ton ) |

120.5 |

116.35 |

0.97 |

section's girder heigh |

positive

moment area |

2200 |

1980 |

0.90 |

negative

moment area |

2200 |

1980 |

0.90 |

3.5% reduction

of steel amount¡ægirder height 10% reduction(220cm¡æ198cm)

|

¡¡

The

method of improving stiffness at the inner support

in the steel box girder. |

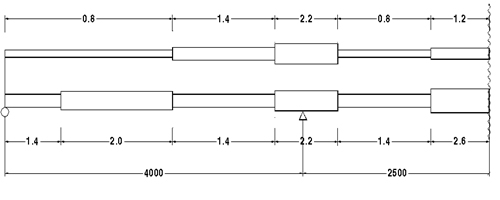

40m-50m-40m45m 3

span continuous bridge's section property and comparison

in the amount of materials 40m-50m-40m45m 3

span continuous bridge's section property and comparison

in the amount of materials

Reduced effect of

steel materials. Reduced effect of

steel materials.

Flange's thickness and hight's simultaneous reduction

and maximum curtailment

of steel amount

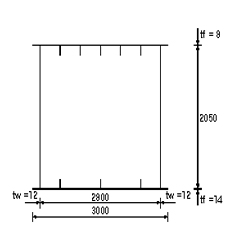

existing steel box gird bridge's section property

existing steel box gird bridge's section property

steel : SM 490

concrete : floor plate 270 Kg/§²

The main position's

section The main position's

section

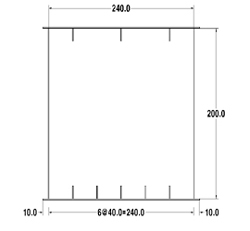

positive moment area |

negative moment area |

|

|

TU=1.2

cm , TL=1.4 cm |

TU=2.6

cm , TL=2.6 cm |

The variation of flange

The variation of flange

|

¡¡

The

method of improving stiffness at the inner support

in the steel box girder. |

improved steel box

gird bridge's section property improved steel box

gird bridge's section property

steel : SM490

concrete

: The floor plate - 270 Kg/§² casting concrete :-400

Kg/§²

The main position's

section The main position's

section

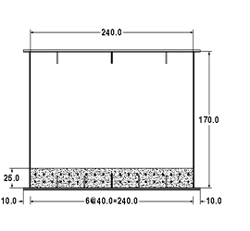

positive moment area |

negative moment area |

|

|

TU=0.8

cm , TL=2.0 cm |

TU=2.2

cm , TL=2.2 cm |

The variation of flange

The variation of flange

The section and

the amount of materials's comparison The section and

the amount of materials's comparison

|

existing method |

Lifting

Support |

L.S/Existing

|

Steel (ton ) |

155.14 |

116.35 |

0.97 |

concrete (ton ) |

493 |

520 |

1.05 |

section's girder heigh |

positive

moment area |

2000 |

1880 |

0.94 |

negative

moment area |

2000 |

1880 |

0.94 |

girder height

6% reduction a condition ¡æ14.9% reduction of

steel amount

|

¡¡

The

method of improving stiffness at the inner support

in the steel box girder. |

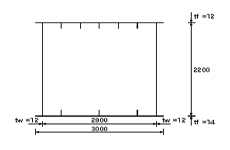

The effect of reduction

on girder height The effect of reduction

on girder height

flange's thickness and hight's

simultaneous reduction and maximum curtailment of

girder height

The

main position's section The

main position's section

positive

moment area |

TU=1.2

cm , TL=1.4 cm

existing

method |

TU=0.8

cm , TL=2.6 cm

Lifting

Support method |

negative

moment area |

TU=2.6

cm , TL=2.6 cm

existing

method |

TU=2.6

cm , TL=2.8 cm

Lifting

Support method |

The

section and the amount of materials's comparison The

section and the amount of materials's comparison

|

existing method |

Lifting

Support |

L.S/Existing

|

Steel (ton ) |

155.14 |

148.02 |

0.95 |

Concrete (ton ) |

493 |

520 |

1.05 |

section's girder heigh |

positive

moment area |

2000 |

1700 |

0.85 |

negative

moment area |

2000 |

1700 |

0.85 |

4.6% reduction

of steel amount¡ægirder height 15% reduction(200cm¡æ170cm)

|

¡¡

The

method of improving stiffness at the inner support

in the steel box girder. |

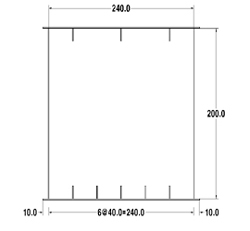

The example of design The example of design

2@65m 2 span continuous

bridge 2@65m 2 span continuous

bridge

The main position's

section The main position's

section

positive moment area |

negative moment area |

|

|

TU=1.0

cm , TL=2.0 cm |

TU=2.6

cm , TL=2.2 cm |

The variation of

flange The variation of

flange

a reference a reference

In the case flange width of section presented in the

example of design is 3m , extensible maximum span

length is possible to 75m.

|

¡¡

The

method of improving stiffness at the inner support

in the steel box girder. |

65m-75m-65m 3 span

continuous bridge 65m-75m-65m 3 span

continuous bridge

The main position's

section The main position's

section

positive moment area |

negative moment area |

|

|

TU=1.6

cm , TL=2.2 cm |

TU=3.2

cm , TL=2.4 cm |

The variation of

flange The variation of

flange

a reference a reference

In the case flange

width of section presented in the example of design

is 3m , extensible maximum span length is

possible to 75m.

|

¡¡

The

method of improving stiffness at the inner support

in the steel box girder. |

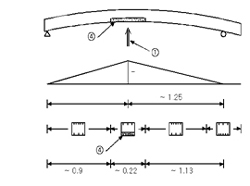

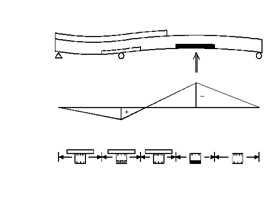

The process of construction

work in 3span continuous bridge The process of construction

work in 3span continuous bridge

1?is lifting-up support,

2?is lifting-down support, 3?points slab concrete and

4?indicates concrete that is cast in lower part

of the steel box girder at the range

of negative

moment.

|

|

The state of lifting-up support after

connecting 2 spans first among 3 spans and then casting and curing concrete in

lower part of the steel box girder at the

negative moment range of the first

inner support. In this place projection

of right-hand is connected part of

the 3 spans.

¡¡

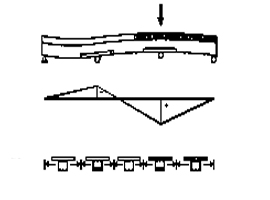

|

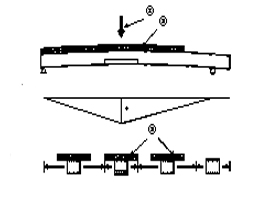

The

state of lifting-down inner support that

was lifted up after casting and curing concrete over full span except left-hand parts

of the third support in condition of lifting-up

the first inner support. |

|

|

The state of lifting-up support to induce compression stress to concrete in

lower part of the steel box girder

after casting and curing concrete in lower

part of the steel box girder at the

negative moment range of the right-hand

support

¡¡

|

The

state of setting to support in condition

of lifting-up right-hand support after

casting and curing concrete in remaining spa |

|

¡¡

The

method of improving stiffness at the inner support

in the steel box girder. |

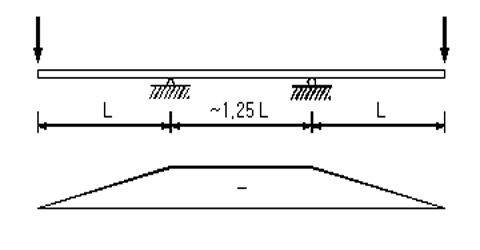

simple-multi span

steel box girder bridge for rahmen by Down-up.(patent

a public notice Number. 10-2000-058716) simple-multi span

steel box girder bridge for rahmen by Down-up.(patent

a public notice Number. 10-2000-058716)

This method in simple pan composite

girder construct is treated as fixed-moved support and

it has fall-rise moved support It have introduce

compressing stress on the floor slab concrete of negative

moment area and the lower flange of positive moment

in fixed support. The method of construct in multi-span

composite girder structure have fall-rise a pier

part support of both ends. It have the floor slab

con'c of inner support and the lower flange of

positive moment area introduce compressing stress. Because

moment in fixed support is distributed at a bridge pier,

share about external force of beam is reduced. So

girder height and span can expect reduction and extension

effect about 20%. Moreover, Parapet wall of one

side abutment in fixed support and floor slab con'c

places as one body therefore expansion joint and lower part can realize excellent effect and it has considerable

aseismicity. In the multi-span case, because support's

falling and rising work is accomplished in

a bridge pier, work's convenience and safety being superior

by far. And it can remove construction joint's

occurrence by simultaneous placing of floor

slab con'c.

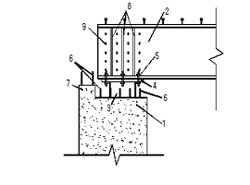

This method in

simple-span can happen big moment in fixed support. First

it has buried H-steel and after welding of connection

plate for steel box the lower part flange's connection

on the upside, it has connect completely by lower

part flange and bolt or welding. Here, at bridge seat

and parapet wall take out bar in advance. Including

the upper part floor slab, bridge seat, parapet wall

and steel box girder's web also lower part flange

is placed the same time. So it can do part of complete

fixed support. Steel box girder is reinforced by

install of stiffener. Not only the upper flange

steel girder but web install the stud, there it has greatly

improved the con'c composite effect. |

¡¡

The

method of improving stiffness at the inner support

in the steel box girder. |

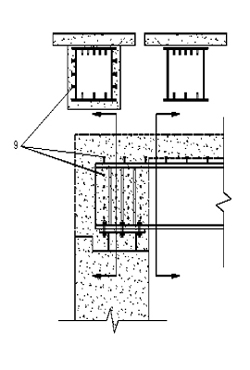

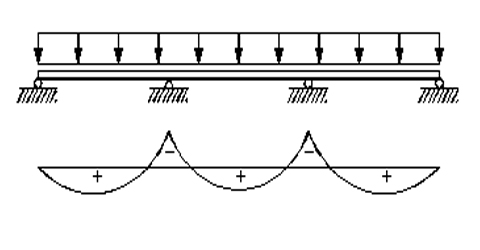

2span continuous

steel box gird composition bridge 2span continuous

steel box gird composition bridge

simple span steel box gird

composition bridge |

2span continuous steel box

gird composition bridge |

After

steel is installed simply, one end is fixed

and other end is downed state |

After

steel is installed extend 2 span, on the

base of inner support part,

state

that is downed both abutment part |

state

that placing floor slab con'c extend all

section |

state

that placing floor slab con'c extend all

section |

After

floor slab con'c is cured,

state

that compressed stress is introduced in

floor slab con'c that has risen

movement

support |

After

floor slab con'c is cured,

state

that compressed stress is introduced in

floor slab con'c that has risen

both

abutment part's support point |

|

¡¡

The

method of improving stiffness at the inner support

in the steel box girder. |

The process of construction

work in 3span continuous steel box gird composition

bridge The process of construction

work in 3span continuous steel box gird composition

bridge

After

steel is installed extend 3 span, on the

base of the 2,3 inner support part,

state that is downed both abutment

part |

state

that placing floor slab con'c extend all

section |

After

floor slab con'c is cured, state that

compressed stress is introduced in floor

slab con'c that has risen both abutment

part's support point |

|

¡¡

|

|

|

|