| |

|

Improvement of bridge's

ability and repair&reinforcement method

Improvement of ability

method of simple and continuous span P.S.C

and

the Preflex composite bridge by Up-Down Method |

Improvement

of ability and repair&reinforcement method of P.S.C

and the Preflex continuous beam

bridge Improvement

of ability and repair&reinforcement method of P.S.C

and the Preflex continuous beam

bridge

( patent 10-1999-007572,

patent 10-1999-045825, patent 10-1999-04582)

1. Introduction

1. brief

beam bridge of P.S.C & Preflex connecting

existing simple method is acted constructal moment redistribution.

At this time , because it occur negative moment in continuous

span , concrete of slab is cracked and problem of a

drop bridge' persistence is occured.

[this

method of construction is improvement of ability method

introducing the compressive force using Up-Down

Method at concrete of slab negative moment.

this method improve by DB-24 then existing P.S.C and

the Preflex.

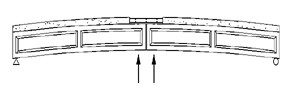

2. construction method

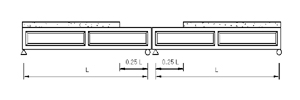

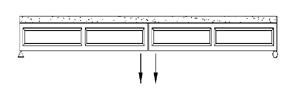

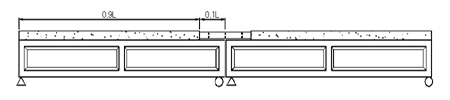

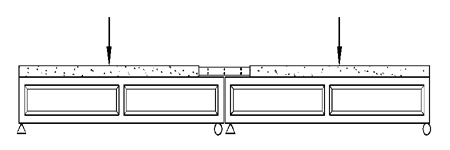

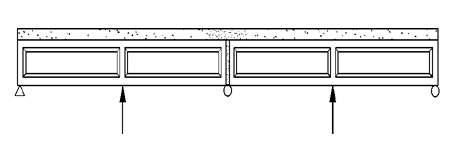

1) this method of construction part removing

slab

after removing slab at negative moment

of P.S.C and the Preflex., it arrange reinforce and

make concrete except the section inside support 0.1L.

this time, cross beam lower neutrality axis make concrete.

then the remander section is made concrete, cure the

concrete surface, after down, finish.

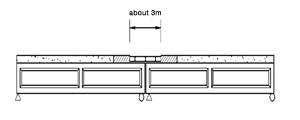

2) this method of construction entirety

removing slab

after

removing the entirety slab., it make concrete

at the section positive moment. then cure the concrete

surface, up support, it make concrete at the section

negative moment, it is finished making bridge by down

support.

|

Improvement of bridge's

ability and repair&reinforcement method

Improvement of ability

method of simple and continuous span P.S.C

and

the Preflex composite bridge by Up-Down Method |

repair&reinforcement

method repair&reinforcement

method

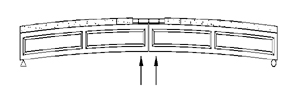

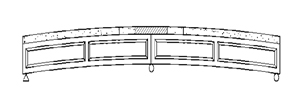

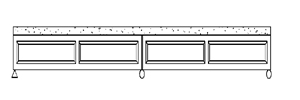

1. simple bridge

when it need to change slab of existing bridge,

equal upper step. only addition breaking concrete.

if existing bridge slab do not change, the step is the

next.

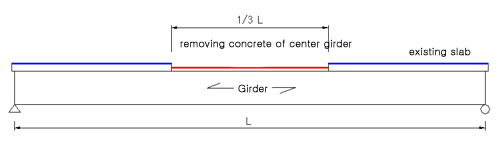

removing concrete of center

girder( preserving existing reinforced rod) |

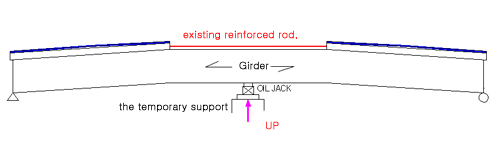

equipping the temporary

support & up girder |

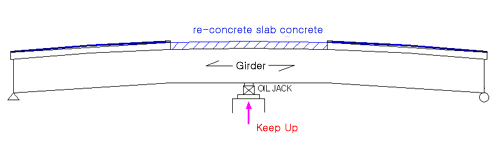

concrete

slab concrete at center and cure the

concrete surface. |

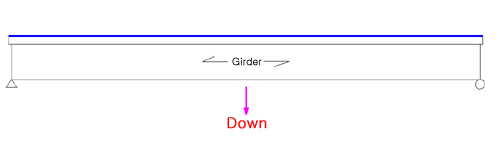

remove the temporary support and

falling girder ( introducing compressive

at the lower part girder) falling

|

|

¡¡ ¡¡

Improvement of bridge's

ability and repair&reinforcement method

Improvement of ability

method of simple and continuous span P.S.C

and

the Preflex composite bridge by Up-Down Method |

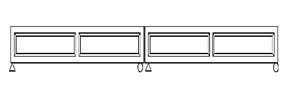

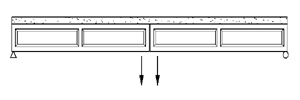

2. continuous

bridge

improvement ability

method's step of continuous 2 span P.S.C & Preflex

composite bridge by part removing slab method improvement ability

method's step of continuous 2 span P.S.C & Preflex

composite bridge by part removing slab method

production

step |

construction

step |

order chart |

STEP1 |

part removing

slab concrete & connecting |

|

STEP2 |

concreting

partly slab concrete |

|

STEP3 |

up inner support |

|

STEP4 |

entirety

removing slab concrete |

|

STEP5 |

down inner

support |

|

STEP6 |

completion |

|

|

Improvement of bridge's

ability and repair&reinforcement method

Improvement of ability

method of simple and continuous span P.S.C

and

the Preflex composite bridge by Up-Down Method |

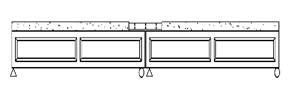

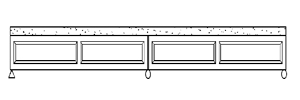

improvement

ability method's step of continuous 2 span P.S.C &

Preflex composite bridge by entirety

removing slab method improvement

ability method's step of continuous 2 span P.S.C &

Preflex composite bridge by entirety

removing slab method

production

step |

construction

step |

order chart |

STEP1 |

part removing

slab concrete & connecting |

|

STEP2 |

concreting

partly slab concrete |

|

STEP3 |

up inner support |

|

STEP4 |

entirety

removing slab concrete |

|

STEP5 |

down

inner support |

|

STEP6 |

completion |

|

|

Improvement of bridge's

ability and repair&reinforcement method

Improvement of ability

method of simple and continuous span P.S.C

and

the Preflex composite bridge by Up-Down Method |

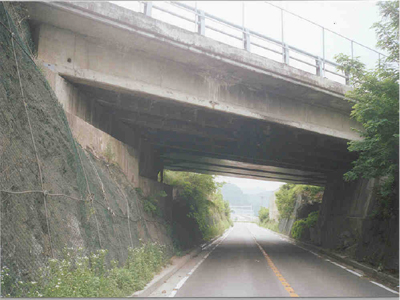

effect improvement

ability of existing bridge effect improvement

ability of existing bridge

1. simple bridge

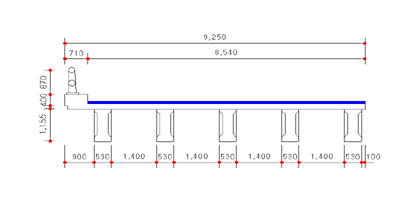

the subject

bridge : the location Imshhil-Gun ,Chollabuk-Do, simple

support PSC Beam

bridge, Sasun overhead bridge

length

of girder 17.4m, length of bridge 18m, wide of bridge

9.25m

It has

been completed at 1973 , the second grade

effect : The basis durability increases

form DB-20 to DB-29

<a panoramic view>

<cross view>

|

Improvement of bridge's

ability and repair&reinforcement method

Improvement of ability

method of simple and continuous span P.S.C

and

the Preflex composite bridge by Up-Down Method |

Sasun overhead

bridge of The rising quantity, the falling quantity

and occurring stress at final

step Sasun overhead

bridge of The rising quantity, the falling quantity

and occurring stress at final

step

classification

¡¡ |

inner

span |

outside

span |

the rising force

¡¡ |

11.97 ton |

13.68

ton |

the falling force

¡¡ |

-17.79

ton |

-19.51

ton |

the rising displacement

¡¡ |

0.63

cm |

0.72

cm |

the falling displacement

¡¡ |

-0.42

cm |

-0.46

cm |

final stress

¡¡ |

the lower

beam

¡¡ |

-2.24

Kg/cm2

(compressive) |

10.69

Kg/cm2

(tension) |

the

upper slab

¡¡ |

-50.66

Kg/cm2

(compressive) |

-56.25

Kg/cm2

(compressive) |

classification

¡¡ |

before

improvement of ability |

after

improvement of ability(basic design) |

the

comparison |

Sasun

overhead

bridge

(L=18.0m) |

design load

¡¡ |

DB_18 |

DB-24 |

|

The basis durability

¡¡ |

DB-20 |

DB-29 |

45%

increase |

|

Improvement of bridge's

ability and repair&reinforcement method

Improvement of ability

method of simple and continuous span P.S.C

and

the Preflex composite bridge by Up-Down Method |

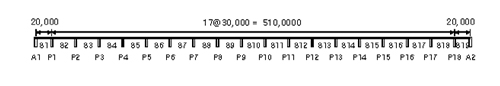

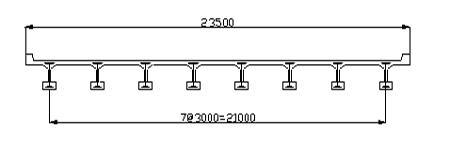

2. continuous

bridge ( basic design )

the subject bridge : the

location Ulsan city, simple support of 20m span , continuous

2 span of 20m span & continuous 3 span of 30m span,

PSC Beam bridge. the subject bridge : the

location Ulsan city, simple support of 20m span , continuous

2 span of 20m span & continuous 3 span of 30m span,

PSC Beam bridge.

length

of girder 550m

the

second grade

effect

: The basis durability increases form DB-18 to DB-37

yaemdong direction

myoungchondong

direction

myoungchon large bridge's general

view

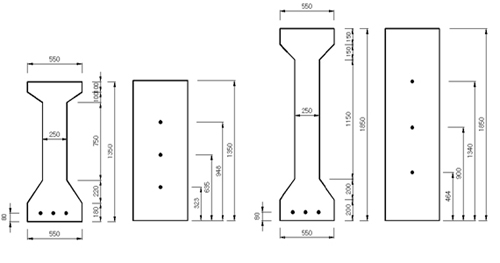

(a) center of span |

(b) end point

of span |

(a) center of span |

(b) end point

of span |

20m PSC Beam's general view 30mPSC

Beam's general view

¡¡ |

Improvement of bridge's

ability and repair&reinforcement method

Improvement of ability

method of simple and continuous span P.S.C

and

the Preflex composite bridge by Up-Down Method |

myoungchon

large bridge's of The rising quantity, the falling quantity

and occurring stress at

final step myoungchon

large bridge's of The rising quantity, the falling quantity

and occurring stress at

final step

classification |

PSC Beam span L=30m

¡¡ |

continuous

2 span

|

continuous

3 span |

the rising force |

24.59

ton |

14.28

ton |

the falling force |

-17.64

ton |

-8.26

ton |

the rising displacement |

6.22

cm |

3.61

cm |

the

falling displacement |

-3.86

cm |

1.81 cm |

final

stress |

the

section of positive moment |

the lower beam |

12.31 Kg/cm2

(tension) |

10.69 Kg/cm2

(tension) |

the

upper beam |

-86.57

Kg/cm2

(compressive) |

-88.50

Kg/cm2

(compressive) |

the

upper slab |

-14.79

Kg/cm2

(compressive) |

-16.33 Kg/cm2

(compressive) |

the

section of negative moment |

the

lower beam |

-131.4

Kg/cm2

(compressive) |

-114.71

Kg/cm2

(compressive) |

the

upper beam |

16.46

Kg/cm2

(tension) |

-5.42

Kg/cm2

(compressive) |

the

upper slab |

12.75 Kg/cm2

(tension) |

0.47

Kg/cm2

(tension) |

classification

¡¡ |

before improvement

of ability |

after improvement

of ability(basic design) |

the

comparison |

simple

support(L=20m) |

design load |

DB-18 |

DB-24 |

¡¡ |

The basis durability |

DB-18 |

DB-26 |

30%

increase |

continuous

2 span (L=20m) |

design load |

DB-18 |

DB-24 |

¡¡ |

The basis durability |

DB-20 |

DB-33 |

65%

increase |

continuous

3 span (L=30m) |

design load |

DB-18 |

DB-24 |

¡¡ |

The basis durability |

DB-20 |

DB-37 |

85%

increase |

|

Improvement of bridge's

ability and repair&reinforcement method

Improvement of ability

method of simple and continuous span P.S.C

and

the Preflex composite bridge by Up-Down Method |

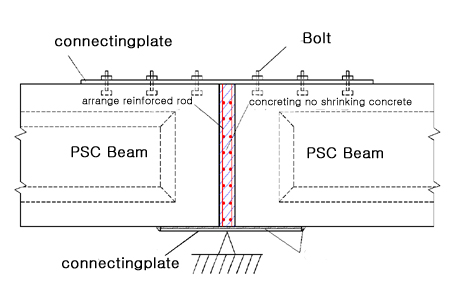

the method

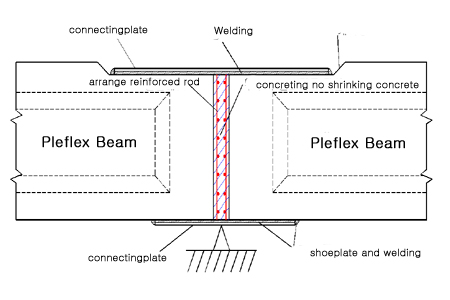

connecting at the section inside support the method

connecting at the section inside support

it is point that

bending tension moment at upper girder and bending compression

moment at upper girder for continuing P.S.C and the

Preflex Beam.

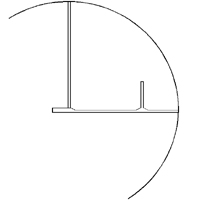

1. method A (P.S.C Beam)

For bending tension stress at continuing

support using chemical anchor at PSC Beam's

upper, it correspond effectively, and connecting

with girder is planed for compressive

stress at lower girder.

Fig. a

Fig. a (the method connecting P.S.C

Beam)

2. method B (Preflex Beam)

bending tension stress at

connecting at the section support at upper girder and

compressive stress at lower girder is corresponded by

effectively connecting Beam

and Beam.

Fig. b (the method connecting Preflex

Beam)

|

Improvement of bridge's

ability and repair&reinforcement method

improvement

of ability method using crack-fasten of P.S.C Beam acting

bending crack |

improvement

of bridge's ability and repair&reinforcement method

* improvement

of bridge's ability and repair&reinforcement method

*

<improvement of ability method using crack-fasten

of P.S.C Beam acting bending crack>

( patent number 10-1999-007572 , patent number

10-1999-045825 ,

patent number 10-1999-04582

)

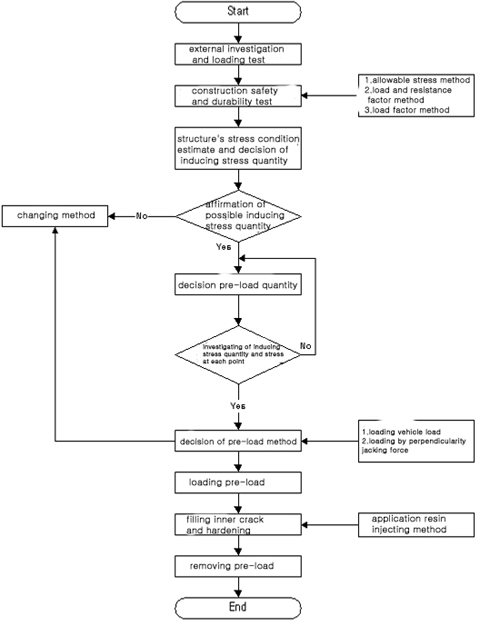

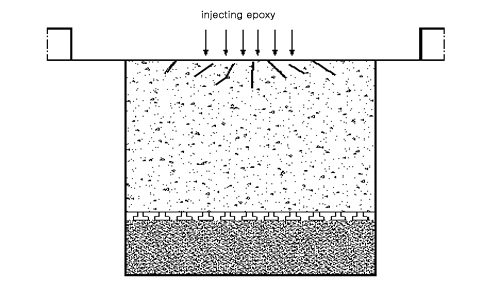

1. outline

Presently existing bridge have many problem.

so it require repair & reinforcement

existing

method of repair & reinforcement have variety problem.

this method of construction overcome the

problem of other existing method of repair

& reinforcement : it is made improvement of unreliable

injecting by loading pre-load at structure

occurring bending crack and pure into injection. then

it is made improvement of repair & reinforcement

by getting rid of pre-load. the reason is

that bending crack concrete occur compressive stress.

so this method of repair & reinforcement

is fitting and trusting.

|

Improvement of bridge's

ability and repair&reinforcement method

improvement of ability

method using crack-fasten of P.S.C Beam acting bending

crack |

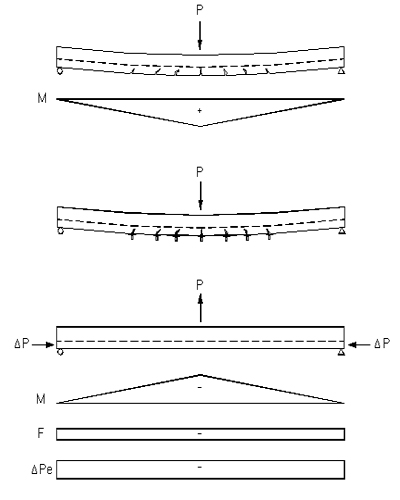

construction

step and stress view construction

step and stress view

¡¡ |

Improvement of bridge's

ability and repair&reinforcement method

Iimprovement of ability

method using crack-fasten of P.S.C Beam acting bending

crack |

¡¡

Fig. 2 force of construction by stages

Fig. 3 effect of inducing stress

¡¡ |

Improvement of bridge's

ability and repair&reinforcement method

improvement of ability

method using crack-fasten of P.S.C Beam acting bending

crack |

experiment

view experiment

view

(a)

loading pre-load (b)

injecting epoxy resins

and

curing the concrete surface

Fig. 4 loading pre-load and injecting

epoxy resins

Fig. 5 being completed hardening of

injecting

table 1 loading-deflection relationship

load |

deflection

before repair&reinforcement |

deflection

after repair&reinforcement |

measuring

date of experiment |

analysis

of finite element |

measuring

date of experiment |

analysis

of finite element |

3 |

5.78 |

6.89 |

5.06 |

5.62 |

6 |

14.16 |

13.79 |

9.26 |

11.24 |

9 |

20.47 |

20.68 |

13.88 |

16.87 |

12 |

25.73 |

27.58 |

23.94 |

22.48 |

16 |

36.4 |

36.77 |

26.6 |

29.97 |

20 |

45.50 |

45.96 |

37.5 |

34.46 |

24 |

- |

- |

45.27 |

44.95 |

28 |

- |

- |

52.43 |

52.44 |

32 |

- |

- |

60.50 |

59.94 |

34 |

- |

- |

65.95 |

63.68 |

37 |

- |

- |

72.00 |

69.3 |

this date is showed : comparing measuring

date of experiment with analysis of finite

element

|

Improvement of bridge's

ability and repair&reinforcement method

improvement of ability

method using crack-fasten of P.S.C Beam acting bending

crack |

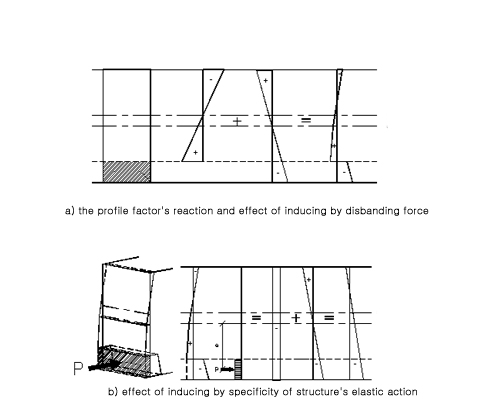

comparing a method of

construction comparing a method of

construction

we apply this method to simple

PSC composition beam of reinforcing as External

Prestressing method. then we compare stress condition

* the subject bridge

: moonle overpass

* the time

of completed : 1979

* type of

upper structure :single span PSC composit beam

*

external state : deterioration of slab and girder, crack

occur at PSC beam, bending

crack length 20~80cm, wide 0.1~0.3m. result of

crack's deep, crack exceed

reinforce rod's cover.

so

need structural reinforcement.

*

profile factor's rate : 15%

Fig. 6 moonle overpass's cross section

|

Improvement of bridge's

ability and repair&reinforcement method

improvement of ability

method using crack-fasten of P.S.C Beam acting bending

crack |

|

table 2 comparing stress in service load

classification

¡¡ |

upper section

Kgf/cm2 |

low section

Kgf/cm2 |

the

comparison |

stress

before

damage |

DB-18 |

-91.23 |

12.07 |

exceeding

allowance stress |

DB-24 |

-97.88 |

32.92 |

stress after damage |

DB-18 |

-96.29 |

39.89 |

DB-24 |

-102.94 |

60.79 |

External

Prestressing |

DB-18 |

-77.29 |

-12.60 |

satisfactory

design load |

DB-24 |

-83.93 |

8.3 |

Preloading |

DB-18 |

-91.16 |

-4.20 |

DB-24 |

-97.81 |

16.70 |

resulting of comparing this method to External

Prestressing method by inducing at simple PSC

beam, the lower part of PSC beam inducing stress

quality is smaller 8.4kgf/cm2 then External Prestressing

method, but this method secure durability except

additional repair&reinforcement method.

|

Improvement of bridge's

ability and repair&reinforcement method

Repair method at inner

support of continuity Steel Box Girder using injection

concrete |

Repair method

at inner support of continuity Steel Box Girder using

injection concrete Repair method

at inner support of continuity Steel Box Girder using

injection concrete

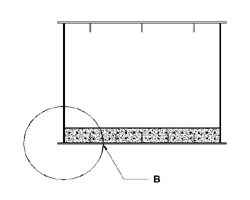

1. outline

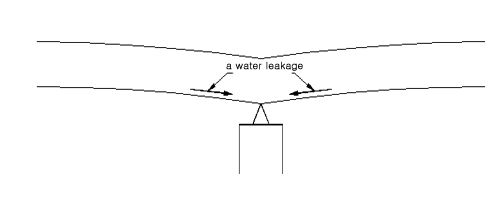

This method is repair method

: after clearing rot, lowering stiffness is repair.

* rotting of inner support in Box wall

water store at inner support

because of camber. so it occur rotting of inner

support in Box wall

Fig. 1 flow of water leakage

by camber

* Repair method using injection concrete

if rotting of inner support in

Box wall is removed like Fig. 2 , thickness of flange&web

is drop and stiffness is reduction.

Fig. 2 Box inner wall occurring

rot

|

Improvement of bridge's

ability and repair&reinforcement method

Repair method at inner

support of continuity Steel Box Girder using injection

concrete |

¡¡

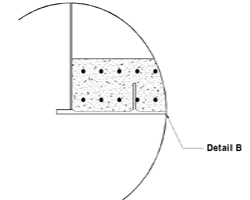

Fig. 3 after removing

corrosion

Fig.4 Being reinforced at section

negative moment by injecting concrete.

|

Improvement of bridge's

ability and repair&reinforcement method

improvement of continuity

bridge's ability method using weight |

|

1. outline

Presently existing continuity bridge

was constructed without preparing negative moment

at inner support. so slab concrete was cracked and stiffness

and durability was decline. finally, this

crack is made dark action as structure and dark

effect as using & durability.

improvement

of continuity bridge's ability method using weight is

a method introducing compressive stress

at negative moment inner support. so crack is prevented

and this method have an advantage at deflection &

shock.

|

Improvement of bridge's

ability and repair&reinforcement method

improvement of continuity

bridge's ability method using weight |

2. improvement of continuity

bridge's ability method using weight

step 1 removing slab

at section negative moment

step 2 loading

after repairing across beam

load is decided by tension

reinforced rod quantity and moment . this moment is

that across beam's ability resistant.

step

3 removing after concreting slab at section negative

moment

through step 1~step 3 , induce compressive

stress at section negative moment's slab.

so it is

resisted negative moment

acting live load. this method is applied at plate continuous

bridge and steel box continuous bridge's repair method

and over 3 span.

|

Improvement of bridge's

ability and repair&reinforcement method

improvement of continuity

bridge's ability method using weight |

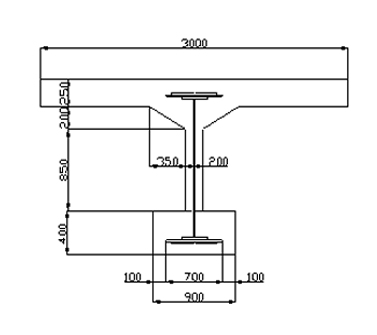

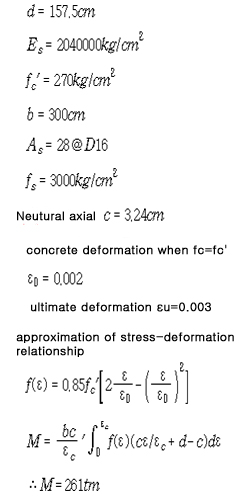

3. structure

computation's example

structure computation perform for

ability application this method , actually constructed

2 span continuous preflex bridge, using

finite element analysis modeling.

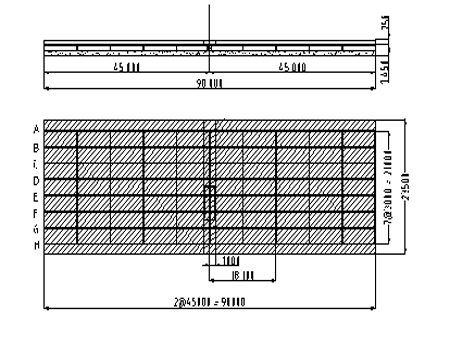

this modeling is 2 span continuous

bridge , span length 45m, this bridge is location

Inchon city,

public overpass.

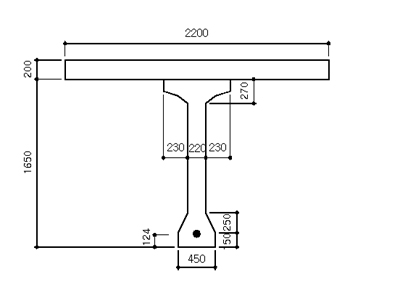

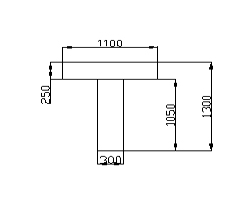

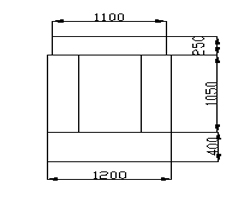

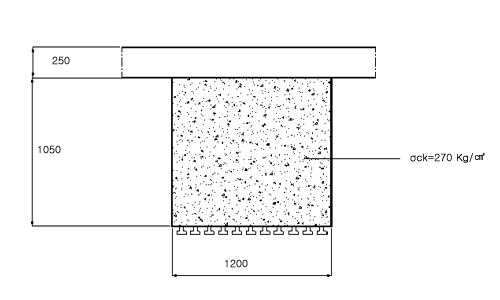

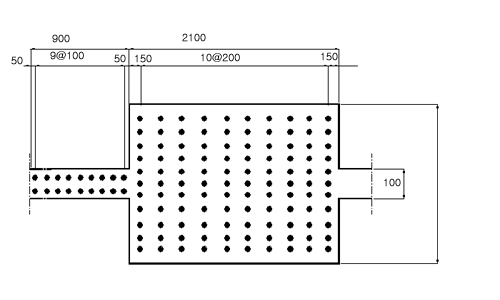

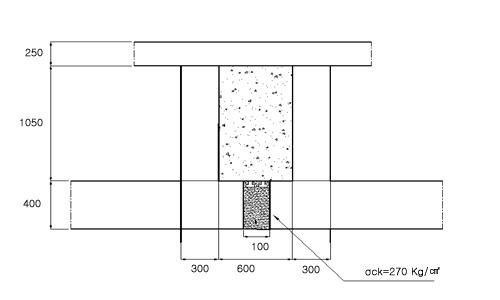

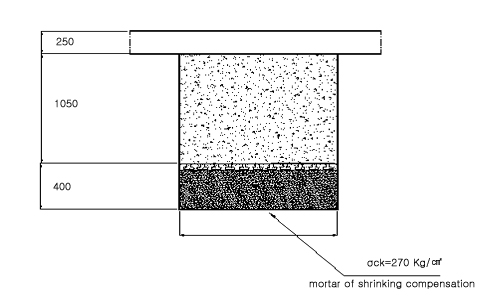

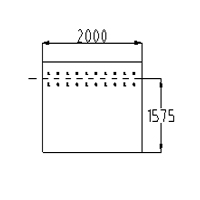

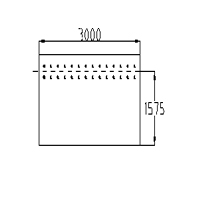

Fig. 1 is cross section view of preflex bridge. Fig.

2 is cross section view of 1 preflex

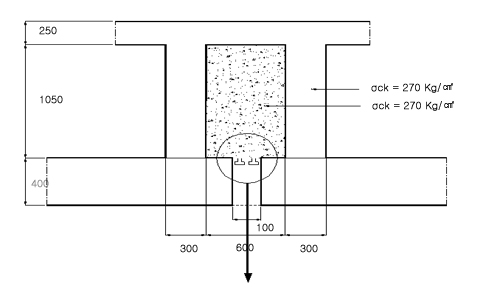

beam. Fig. 3 is cross section view of across beam of

section positive moment and section

negative moment. and table 1, table 2 is section's

character using finite element analysis.

Fig. 1 cross

section view of preflex bridge

table 1 section's character of preflex beam

beam

¡¡ |

beam+slab |

beam |

A |

2524 |

1522 |

Ix |

8678835.2 |

4581683.8 |

Iy |

4634171 |

570109.1 |

J |

1885243.8 |

277118.8 |

Fig. 2 cross section view of preflex

beam

|

Improvement of bridge's

ability and repair&reinforcement method

improvement of continuity

bridge's ability method using weight |

|

table 2 section's character of across

beam and slab

¡¡ |

across

beam |

slab |

across

beam+slab |

across

beam of connecting section |

across

beam of connecting section-slab |

A |

370.6 |

323.5 |

694.1 |

2491.6 |

2168.1 |

Ix |

340477.9 |

16850 |

1087095.2 |

6110930.9 |

3897394.0 |

Ix |

27794.1 |

326225.5 |

354019.6 |

2927906.1 |

2601680.7 |

J |

111176.5 |

67402.0 |

178578.5 |

5880763.4 |

5813361.0 |

¡¡

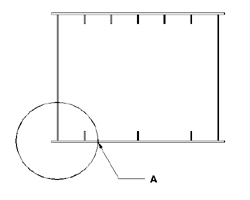

Fig. 3 across beam and slab

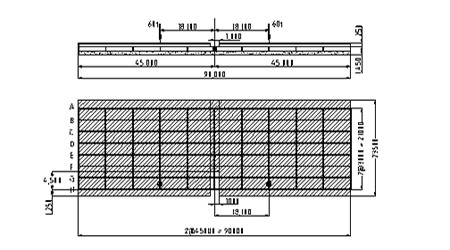

(1) detail construction step

¨ç adhering strut

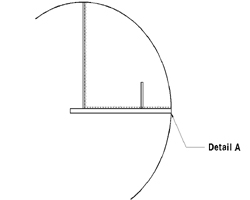

a-1.

cross section of beam

Fig. 4 crossing section with

beam , adhering strut at lower across beam

|

Improvement of bridge's

ability and repair&reinforcement method

improvement of continuity

bridge's ability method using weight |

|

a-2. cross section view of connecting

section

Fig. 5 adhering strut at lower

across beam

b-1. a ground plan ( view at down

)

Fig. 6 adhering strut's shape at down

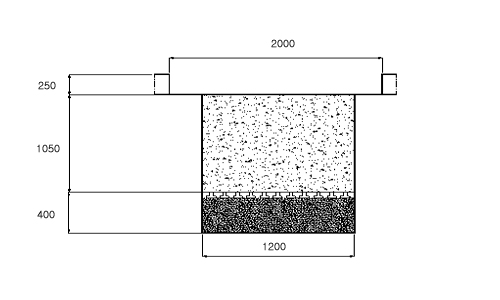

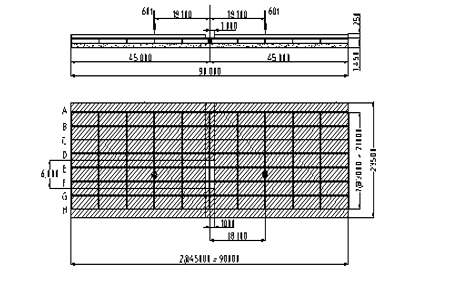

¨è injecting concrete

a-1. cross section of beam

Fig. 7 injecting crossing section

with beam

|

Improvement of bridge's

ability and repair&reinforcement method

improvement of continuity

bridge's ability method using weight |

|

a-2. cross section view of connecting

section

Fig. 8 injecting concrete of

connecting section

¨é removing slab

a-1. cross section

of beam

Fig. 9 removing upper flange at crossing

section with beam

|

Improvement of bridge's

ability and repair&reinforcement method

improvement of continuity

bridge's ability method using weight |

|

a-2. cross section view of connecting

section

Fig. 10 removing upper flange at connecting

section

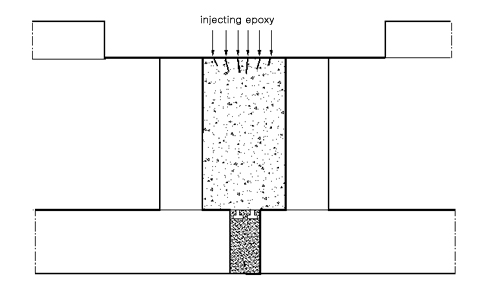

¨ê injecting epoxy at section across

beam crack

a-1.

cross section of beam

Fig. 11 injecting epoxy at across

beam upper cracking section of crossing section

a-2. cross section view of

connecting section

Fig. 12 injecting epoxy at across

beam upper cracking section of connecting section

|

Improvement of bridge's

ability and repair&reinforcement method

improvement of continuity

bridge's ability method using weight |

¨ë loading

a) bending moment of ability

removing slab's across beam

* the out

side of across beam

M=204.5

tm

* inner across beam

|

Improvement of bridge's

ability and repair&reinforcement method

Iimprovement of continuity

bridge's ability method using weight |

|

b) loading weight

result finite element analysis, negative moment 330ton

occur when 100ton load at G beam. so weight is 63.3ton

for occurring negative moment 204.5ton. so weight is

60ton.

c) loading weight

*step 1

Fig. 13 cross section and a

ground plan of loading step 1's weight

*step 3

Fig. 14 cross section and a

ground plan of loading step 3's weight

|

Improvement of bridge's

ability and repair&reinforcement method

improvement of continuity

bridge's ability method using weight |

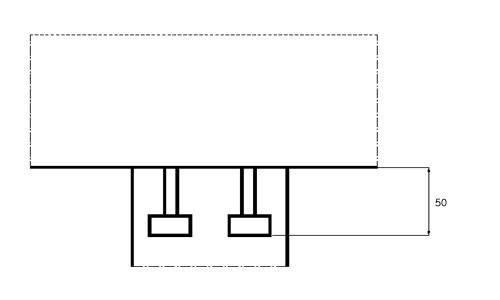

¨ì concreting slab and release

Fig. 15 cross section and a ground

plan of concreting slab and release

(2) final stress

table 4 final stress of weigh and

live load

¡¡ |

the out side

of across beam |

the inner

side of across beam |

the point

of load |

bending

moment by live load

¡¡ |

412.8tm |

412.8 tm |

¡¡ |

upper

stress by live load

¡¡ |

28.57 Kg/cm2

(tension) |

42.85 Kg/cm2

(tension) |

¡¡ |

bending

moment by weigh

¡¡ |

235.32 tm |

248.82 tm |

147 tm |

upper

stress by weigh

¡¡ |

17.53 Kg/cm2

(compession) |

25.8 Kg/cm2

(compression) |

21.9 Kg/cm2

(tension)the (section lower casing) |

final

upper stress

¡¡ |

11.04 Kg/cm2

(tension) |

17.05 Kg/cm2

(tension) |

¡¡ |

|

Improvement of bridge's

ability and repair&reinforcement method

repair&reinforcement

method of pier's coping |

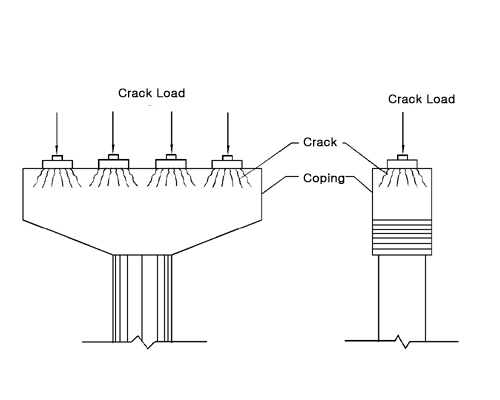

1. outline

this method repair and reinforce crack

acting at pier's coping supporting the upper

part bridge.

Fig. 1 cracking

shape

2. existing method of construction.

|

Improvement of bridge's

ability and repair&reinforcement method

repair&reinforcement

method of pier's coping |

Fig. 2 is existing method of construction. the method

have problem of maintaining

existing method using frequently have many problem.

|

Improvement of bridge's

ability and repair&reinforcement method

repair&reinforcement

method of pier's coping |

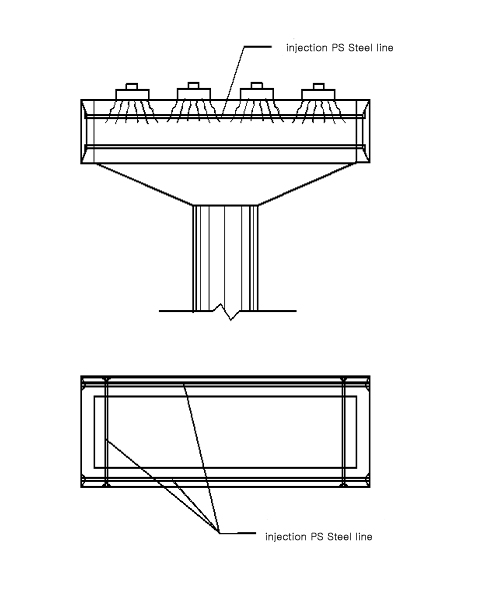

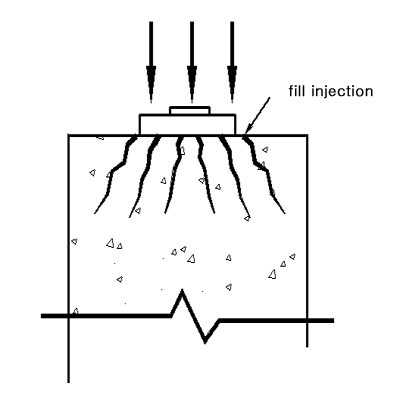

3. construction method

this method is that: after it load

cracking load at coping of acting crack, extend crack.

then using epoxy resins, fill crack, remove load. finishing.

Fig. 3 after cracking load, fill injection

filling injection

3. effect

this method improve 150~200% of practical

coping durability as introducing compressive at total

coping.

|

|

|

|

|