|

¡¡

The existing types of overhead bridge The existing types of overhead bridge

¡¡

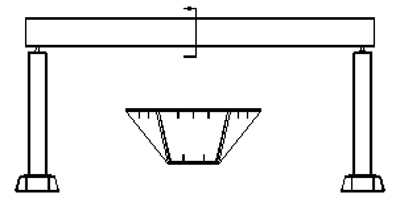

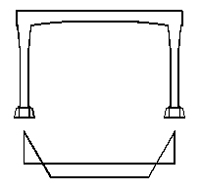

Steel box beam is constructed on upper

column in a placed state as simply supported beam. (Fig. 1) Steel box beam is constructed on upper

column in a placed state as simply supported beam. (Fig. 1)

Because it is simply supported beam, the

steel box section is designed as maximum positive moment occured

at the middle of span. so depth of beam is very large and it is

unshapely. Because it is simply supported beam, the

steel box section is designed as maximum positive moment occured

at the middle of span. so depth of beam is very large and it is

unshapely.

It has so large deformation because simply

supported beam. It has so large deformation because simply

supported beam.

When the beam contract with column, it

is contracted through previousely boiled bolt hole at beam and column

after column is fixed at foundation. so it is cause of poor construction

that column leans or wide the bolt hole by oxygen. When the beam contract with column, it

is contracted through previousely boiled bolt hole at beam and column

after column is fixed at foundation. so it is cause of poor construction

that column leans or wide the bolt hole by oxygen.

fig. 1 Simply supported

overhead brige

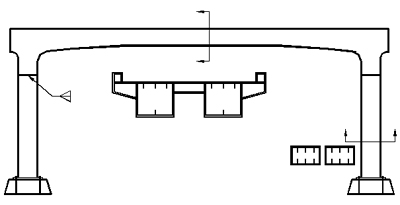

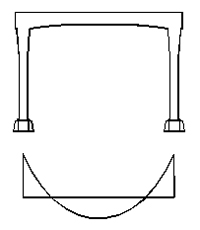

The other structure of existing overhead

brigde is double steel box section and rahmen structure consist

of four column, it has two column at one side. (Fig. 2) The other structure of existing overhead

brigde is double steel box section and rahmen structure consist

of four column, it has two column at one side. (Fig. 2)

Because beam and column section are designed

as double steel box section, it is more disadvantageous then single

steel box section at material using and production. Because beam and column section are designed

as double steel box section, it is more disadvantageous then single

steel box section at material using and production.

When the beam contract with column, a upper

part of column and beam are combined and place it on column after

part of column is fixed at foundation. this method is completed

by welding so there are many poor construction cases that cutting

the column by error of placed in field. When the beam contract with column, a upper

part of column and beam are combined and place it on column after

part of column is fixed at foundation. this method is completed

by welding so there are many poor construction cases that cutting

the column by error of placed in field.

It need more material and expensive than

simply supported beam. It need more material and expensive than

simply supported beam.

Figure 2. Double

steel box rahmen overhread brigde

Characteristics Characteristics

The side of mechanics The side of mechanics

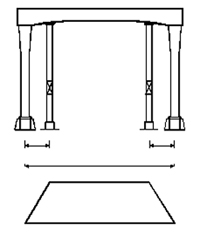

The specific character of this method

is unification of steel box beam and column by welding. The existing

method of simply suported overhead bridge structure is not.

The method, prestressed steel box

rahmen overhead bridge using temporary supporting point, reduce

a third of maximum positive moment compare with existing method

and two thirds of both side negative moment of steel box beam compare

with existing simply supported beam so the hight of middle span

section is reduced compare with existing that. This effect of decreasing

moment not only make it possible construction that is varied the

section at middle and end of span with linear and curvature but

reduce 30% in amount of steel compare with existing simply supported

beam.

In serviceabillity, because the

maximum deformation reduce 20% when use the same amount of steel

by existing method of simply supported beam, it is advantageous.

In construction, it is useful in problem in temperature by contract

beam and column.

The side of an outward form The side of an outward form

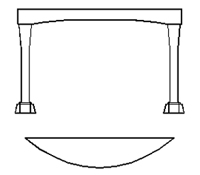

Compare this method with existing

doube steel box rahmen overhead brigde, existing method is similar

to this new method in mechanics. Section of beam is double steel

box and there are two columns at the end of overhead bridge in existing

method. But this new method reduce the materials and advantageous

in construction by use the single steel box, reduce the number of

column to one and large variation at upper section of contract with

single steel box beam compare with lower section.

The side of structure The side of structure

In this method, after steel box

beam is placed on column, the temporary column that can control

the hight as equal to both sides of beam and upper column is instituted

at 1/8¡1/6 point from end of both sides of beam. It make negative

moment so it have prestressing effect that reduce the positive moment

by dead load and live load after contract beam and column. In part

of beam, the effect of prestress is harmful but it is very short.

¡¡

Construction Method Construction Method

Step of construction Step of construction

STEP 1 : Camber and loading of self weight

of steel member STEP 1 : Camber and loading of self weight

of steel member

Sigle steel box beam is placed

on column as linear or curvature varied section |

(fig.

1) Shape diagram and bending moment diagram about the

set single box beam on the existing column |

¡¡

STEP 2 : Set the temporary supported point

and loading of upword load STEP 2 : Set the temporary supported point

and loading of upword load

Set the temporary column that

get the prestressed effect by control the hight and

loading of upword load |

(Fig.

2) Shape diagram and bending moment diagram about creat

the negative moment by temporary spported point |

¡¡

STEP 3 : Remove the temporary supported

point after contract beam and column STEP 3 : Remove the temporary supported

point after contract beam and column

Remove the temporary supported

point(fig. 3) after contract beam and column by welding

and complet the construction of overhead bridge(Fig.

4) |

(Fig.

3) Shape diagram and bending moment diagram about remove

the temporary supported point after contract beam and

column by welding

(Fig.

3) Shape diagram and bending moment diagram about completed

prestressed steel box rahmen overhead bridge using temporary

support |

¡¡

|